A piece we wrote analyzing the application of an article in The New York Times that focused on labor shortages to the fresh produce industry led one eminent professor to send along some intriguing comments.

I found very interesting your article, Future Labor Shortage Poses Problems for Industry.

I agree that skilled labor is in shortage. But there is a “double pincers” of labor shortage and competition from globalization closing on industry from two directions. On the one hand, skilled labor is in shortage and even unskilled labor can be in shortage due to migration limitations. Both of these drive labor costs up (beyond labor cost inflation contributed to by rising health care costs and fuel costs for their transport).

On the other hand, the industry is under a cost squeeze in general due to global competition with globalization. While I am not making a recommendation, I note that historically, industries that face rising costs of a given factor, like labor, substitute away from that factor and into another; generally this is from labor into machines. This substitution is usually accelerated when the industry is under survival pressure from increased cost (and quality) competition.

I have noted in another comment to you that now emerging market countries in Latin America, Asia and South America can produce at lower cost with equivalent quality to produce grown in the US and Western Europe. The upshot of all this is that my guess is that the labor shortage will translate into mechanization. The latter will be, I believe, at a far higher level than previously, a great leap forward, driven by the double pincers noted above.

Precision farming will spill into horticulture. Mechanized harvesting will leap forward. Mechanization of post-harvest processes will jump ahead. I think that many produce farms, warehouses, irrigation systems, sprayers, vehicles and accounting offices in farm areas will be … robots… within 20 years. The burst of innovation recently in farm and farm-related robotics (and other mechanization… as the line between robotics and smart “regular” machines is a fuzzy line) seems similar to me to what happened in the Industrial Revolution in Britain.

There was an accumulation of new machines (for textile mills and steam engines)… on the shelf… for some 60 years before the industrial revolution! Then “suddenly”, farmers (the extreme majority in Britain at that time) had a mini agricultural boom and there was a “tipping point” where they went from being able to buy 1 shirt a year to buying 2 shirts a year! That suddenly doubled demand, putting big pressure on the textile industry, and the latter ran desperately to the scientists and asked them to pull their inventions off the shelf and get them working.

That caused probably the greatest leap forward for human material life since the same sort of thing happened and turned up a new technology called “agriculture” ten thousand years ago. I think that the “double pincers” of labor shortage and globalization will drive farmers (and other produce industry actors) to turn to robotics (and semi-roboticized mechanization) to a far greater extent and range of uses than a mere 10 years ago. This will probably cause those who can afford to buy and have the skilled labor (which will include different skills than what you meant by “skills”; a software expert for example might be the primary category of employee of the future).

Here is a New Zealand example. I was in New Zealand for a few weeks in March and visited various sites. One of them was a large kiwi farm and another was Massey University. The kiwi farmer noted that it was becoming increasingly difficult to source migrant labor or keep it on farm once there, due to alternatives for the migrants. I asked, on a whim, “will you instead mainly use robots in 20 years?” He smiled and said, oh, much sooner that that! He said they already had robots working in their packing sheds. I then went to Massey and saw a prototype of a kiwi harvesting robot, like a go-cart with 4 wheels, GPS to navigate (markers are placed on the poles supporting the canopy), electric eyes to look up at fruit canopy and pick ready fruit by size and shape, works 20 hours a day, picks fruit with 4 extendible arms and then puts the fruit delicately in a chute which then loads a pulled wagon. The robot fills the wagon, drives it back to the warehouse. (I imagine that projecting from the farmer’s remark, a robot might even be there to receive it and unload it.) Then the harvesting robot goes back to orchard navigating by GPS.

The “hands” of the robot are designed for delicacy and chute distance is less of a drop than human pickers did. It does not shake the plant. It leaves the unripe unready fruit for a later pass.

They have also developed one for apple harvesting. They will market these robots. Just like every big shift we have observed in the produce industry (and various other industries), there will be the usual sequence of events once a cluster of these sorts of “robot unveilings” accumulate.

A set of countries and states and companies, as well as labor suppliers, will rush at them, make investments and inventions, corner top skilled labor for this innovation from anywhere in the world, gain advantage, and increase their competitive advantage.

A second group of countries, states, and companies will hold back and assume somehow that “time will tell”.

A third group will resist this technological change born from globalization plus factor price change.

The resistance or avoidance of it will probably only be effective in developing countries where cheap labor can be an effective substitute for robots. Competition will then, as in the computer industry, bring down prices of the factor, and robots will be made even cheaper. Thus, globalization and a series of events that together suddenly push up labor costs will push a great wheel rolling and rolling that will seem to suddenly change the technology of the produce industry, in a decade or two at most.

|

Thomas Reardon Professor Dept. of Agricultural, Food, and Resource Economics Michigan State University Co-Director IFPRI/MSU Joint Program “Markets in Asia”

|

We deeply appreciate Professor Reardon’s thoughtful remarks. That he spends so much of his time amidst the teeming masses of India and yet can still perceive labor shortages is much to his credit — although actually we hear frequently that western-style retailers in India find appropriate help in short supply.

Actually we have dealt many times with issues of mechanization in agriculture. One of the earliest pieces we ran on the immigration issue included a letter from a key buyer:

On immigration, much to the dismay of my shippers, I’ve long contended that the agricultural community is hooked on the drug of cheap labor. In the 60’s, people were mechanically harvesting certain vegetables for Campbell’s Soup. They had to quit doing it because labor was so cheap — they couldn’t beat the cheap labor rates — and the machine wasn’t efficient enough to overcome it. The point is, it was being contemplated 40 years ago, and it should have been an industry-wide effort ever since.

We haven’t worked on mechanization and automation in this industry because we have had no motivation to do so. Now, with fear of labor shortages, we see a frenetic pace of R&D on mechanical harvesters. I’m already hearing tales of at least four companies that will be mechanically harvesting lettuce in Yuma with less than 50% of the labor previously needed, and they also claim better quality! And this is only the start of an industry revolution.

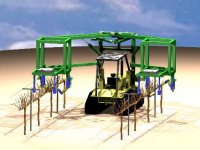

We have also run pieces such as, Reducing Labor With Technology, and in a piece entitled, Compromise Immigration Bill Gets Another Chance, we highlighted a program researching mechanized harvesting technology being funded by the California Citrus Research Board and Washington Tree Fruit Commission. The piece included a review of some of the work done by Vision Robotics and included graphics depicting how mechanical harvesting equipment might look:

Apple Picking

Our vision systems are first used to scan and identify apples within an orchard. Cameras placed at the end of long scanning booms use arrays of stereoscopic cameras to create a virtual 3D image of the entire apple tree. The positions and sizes of the apples are stored and passed onto the harvesting arms. Immediately following the scanning process, a series of long reticulating arms are maneuvered to gracefully pick each apple quickly, efficiently, and economically.

Orange Harvesting

Our vision systems are first used to scan and identify oranges within a grove. Scanning heads placed at the end of multi-axis arms use arrays of stereoscopic cameras to create a virtual 3D image of the entire orange tree. The positions and sizes of the oranges are stored and passed onto the harvesting arms. Immediately following the scanning process, eight long reticulating arms are maneuvered to gracefully pick each orange quickly, efficiently, and economically.

Grape Pruning

At the end of each season, workers must go out into a vineyard and meticulously trim every single vine at a precise angle and location in order to prepare the vines to grow the best grapes the following year.

Yet all this speaks to our technical proficiency, and Professor. Reardon’s letter is really serving to remind us all of simple principles of economics. First, what is feasible depends crucially on the price of alternatives and, second, research and development as well as capital investment flows to where profit opportunities exist.

Whether Professor Reardon is correct that the industry will mechanize quickly depends crucially on two things: What happens to immigration and international trade. That US growers would mechanize quickly if immigrant labor was eliminated and foreign produce could not be imported is clear. Why? It goes back to the two principles of economics Professor Reardon reminds us of. First, if there was no foreign labor, US growers would have to pay more — probably much more to entice a domestic labor force into the fields. Second, if there was no competitive imported produce — assuming consumers still want the product at a higher price — growers could pay higher wages profitably. This would create a demand for robots and the high wages would both incentivise developers of such systems and encourage investment to reduce manpower costs.

Of course these are two big ifs. During the immigration bill debate, we argued that the industry’s best shot for getting a guest worker program would be to ask for a temporary program with a phase-out. In effect making a promise to the American people to gradually mechanize.

Most growers, though, fear to make such a commitment because they fear that labor-rich countries will be able to undercut pricing and export product to the US.

It is hard to know how it will all work out, but of this we are certain: The answer is as likely to be determined by politics as by economics.

Many thanks to Professor Reardon for his thought-provoking remarks.